TR- and TRS-Pinions

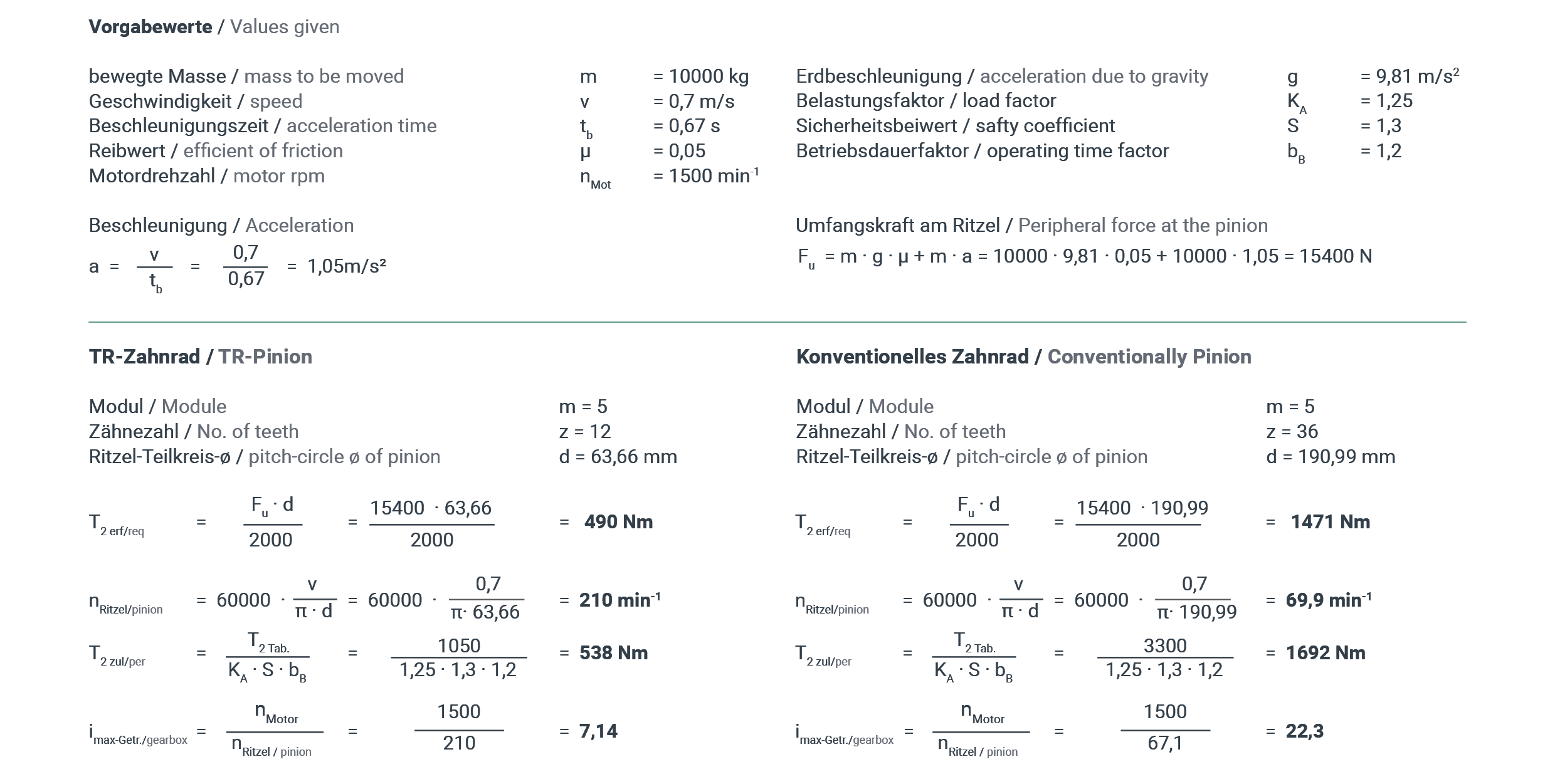

Our high-precision TR- and TRS-Pinions (TR = Torque Reduction; TRS = Torque Reduction Supporter) for highly dynamic applications have been specially developed for use on planetary gears. They comply with the EN ISO 9409-1-A interface. Together with ATLANTA racks they open up new possibilities. The compact dimensions of TR- and TRS-Pinions offer impressive performance: they transmit high circumferential forces and generate low drive torques. This allows you to use smaller and more cost-effective gears and motors without sacrificing performance.

The TR- and TRS-Pinions are manufactured in gear quality 5, which maximises their load capacity. This makes it possible to realise extremely backlash-free and smoothrunning rack drives that offer the highest precision and reliability. Our TR- and TRS-Pinions enable the implementation of highly rigid and highly dynamic drives due to their unique combination of high stiffness, low mass moment of inertia and minimal backlash.

The teeth of the TR- and TRS-Pinions are designed in such a way that it is possible to switch between spur and helical geared drives without having to adjust the centre distance. The bolted flange design also allows for easy replacement of the pinion without having to carry out major disassembly work.

PDF Cataloge TR- / TRS-Pinions

Our TR- /TRS-Pinions offer you a variety of advantages:

- More compact design: The smaller pitch circle diameter saves you valuable installation space in your machine. The compact design allows you to use the available space more efficiently and opens up additional freedom in the design of your system.

- Reduced torque: With a smaller pinion, you reduce the required torque for your rack and pinion drive. At the same time, smaller drives and motors can be used, resulting in cost savings.

- Precise positioning: The smaller pinion reduces backlash and increases the accuracy of your machine. As a result, you achieve more precise positioning and improved quality of your manufactured products.

- Higher accelerations: Thanks to the lower inertia of the smaller gear, higher acceleration and shorter machining times can be realised in your machine.

- Increased linear stiffness: The use of a TR and TRS gear helps increase linear stiffness and improves the precision and repeatability of the entire rack drive. The use of the TRS pinion and a counter-bearing to the gear enables additional stiffness and associated dynamics

and accuracy of your application

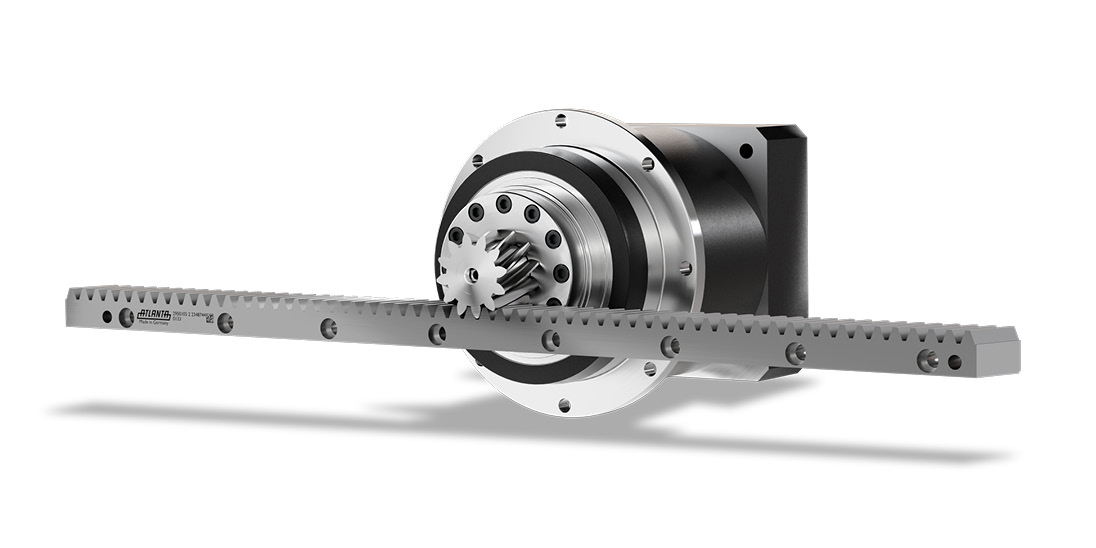

The advantages of TR- / TRS-Pinions with an example calculation:

The following example recalculates 2 pinions for a horizontal travelling operation axis and the suitable planetary gearboxes will be chosen.

The use of an ATLANTA TR- / TRS-Pinion has a major influence on the required torque and therefore on the size of the used planetary gearbox:

Used Pinion TR-Pinion Conventionally Pinion Module and no. of teeth m=5 ; t=12 m=5 ; t=36 Pitch-circle ø of pinion d=63,66mm d=190,99mm Required Torque 490 Nm 1471 Nm Planetary Gearbox Size ø 200mm ø 250mm Gearbox Ratio i=7:1 (1-stage) i=20:1 (2-stage)

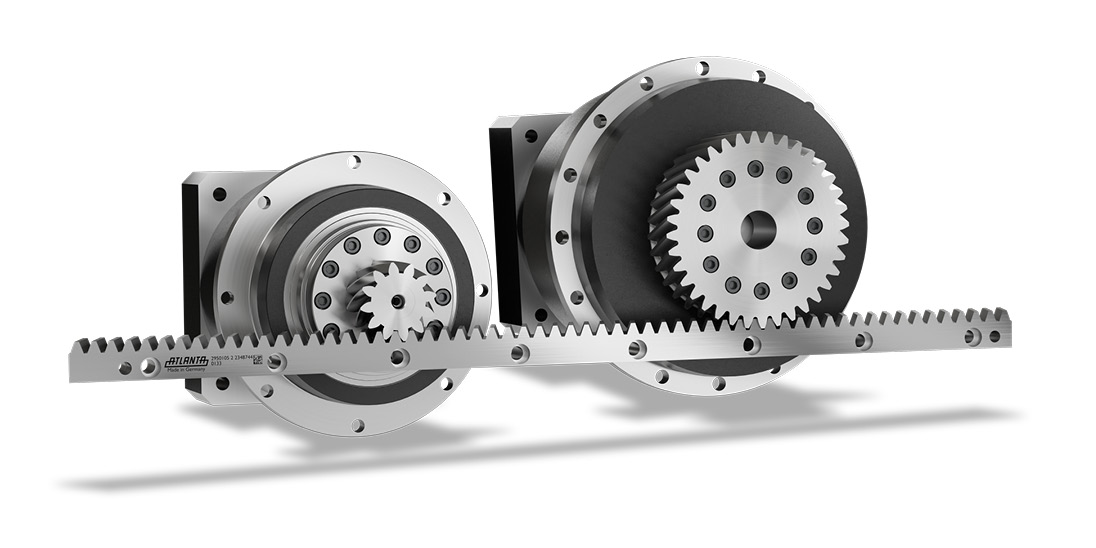

In order to improve the precision of machine tools, the system of electrical preload (adaptive tensioning) is often used. Two drives arranged in parallel are used on a rack and pinion drive or like shown on the picture left, on a rotating ring. These are electronically controlled in such a way that a continuous, dynamic tension is created, which eliminates the play between the rack and gear.

The adaptability of electrical tensioning systems to different operating conditions enables a backlash free change of direction and also increases the flexibility and versatility of the machine tool.

Overall, electrical preload improves the overall performance and reliability of machine tools, which increases the quality of the machined workpieces and the efficiency of the manufacturing processes.